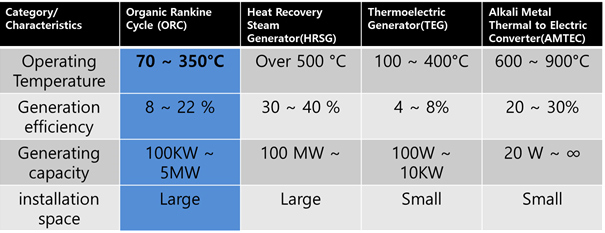

Waste heat recovery system comparison

Waste heat recovery (WHR) system is used for recovering additional power from waste energy sources. Those waste energy sources can be heat sources, heat sink (cold LNG and LCO2) and waste pressure (pressure reduction stations). Representative heat sources are engine waste, geothermal, CSP, CHP, biomass, and etc... The amount of potential energy from waste energy sources are huge, however, the practical applications are limited. There are several reasons why WHR system is not widely accepted. First, WHR system makes the system more complex. It require more components and additional attention for system operation. Second, WHR system highly depends on the main system. When original system is operated at part-load, WHR system must follow the off-load condition or it need to be shut down. Thus, system design for specific system is required. We have studied engine waste heat recovery, waste pressure recovery, cold exergy recovery and other WHR systems.

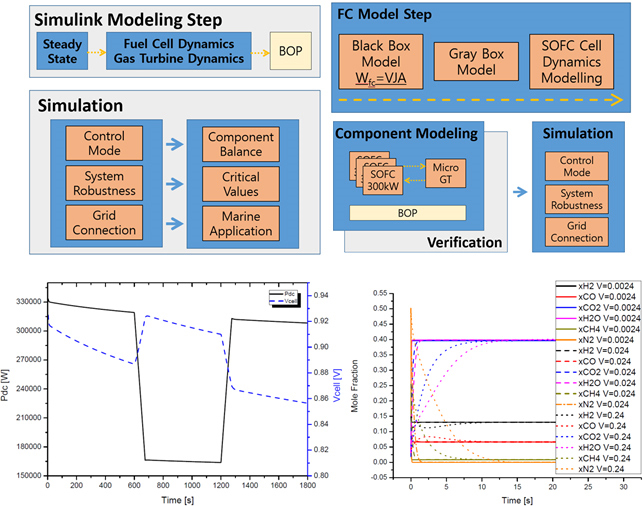

Fuel cell dynamics simulation

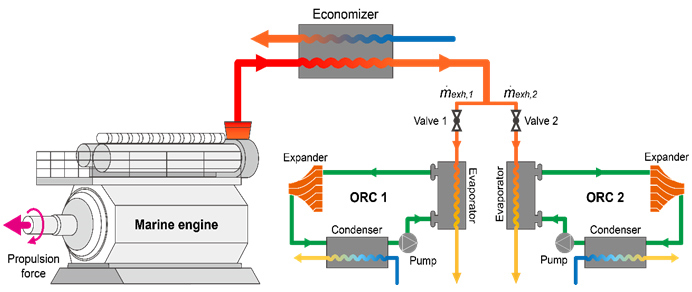

Marine ORC

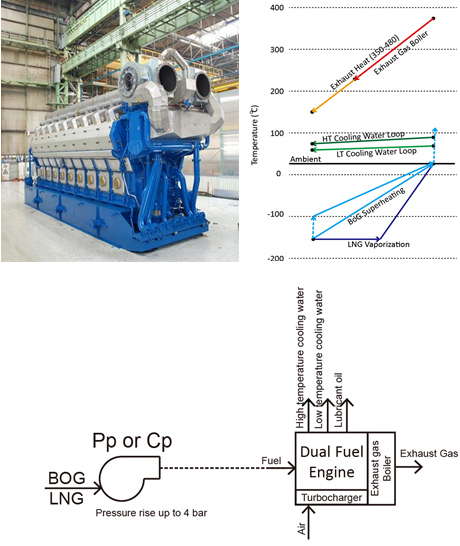

Marine sector consists of 3% of total world greenhouse gas emissions. To reduce those emissions, more efficient propulsion system is required. High efficiency fuel cell engine is a candidate for next generation marine engine. Generally high-temperature fuel cells are considered for large-scale mobile application because direct supply of hydrogen is hard, while methane auto reforming is possible in high temperature fuel cells. The system efficiency can be improved from 45-6% to around 60%. Besides, the overall system efficiency could be increased up to 80% with additional WHR systems. WHR system for marine application can improve 5-10% of original rated power and WHR is also available in current diesel engine. We have been studying the project, "Design and application technology of hybrid power system for marine engine" since 2011. High-temperature fuel cells, diesel and dual fuel engines are covered, and ORC system is considered for WHR system.

ExTENsys Lab

ExTENsys Lab